Data Sheets & Downloads

User Manuals (Current Models):

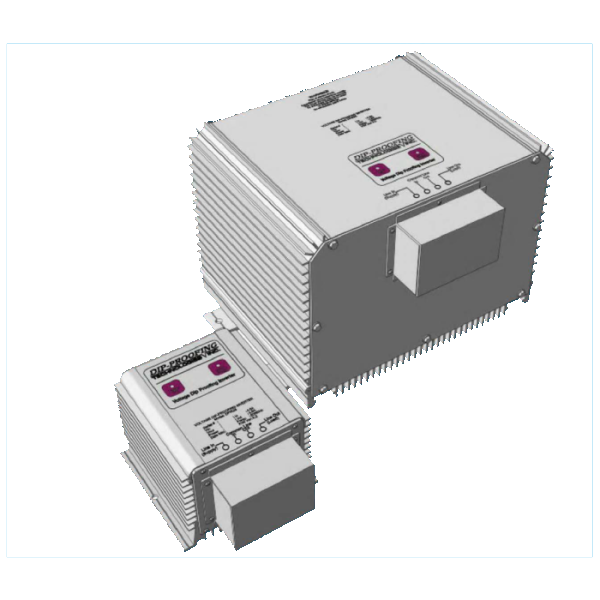

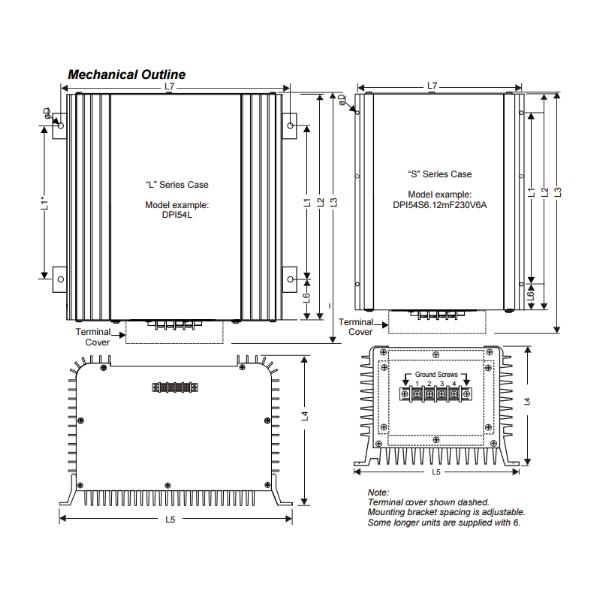

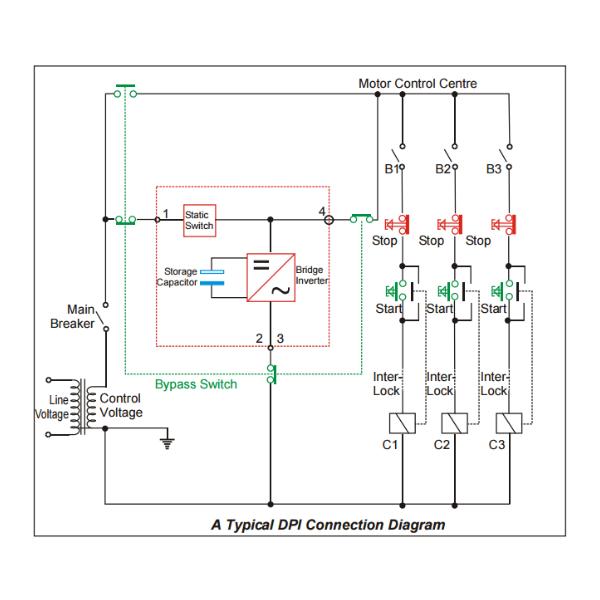

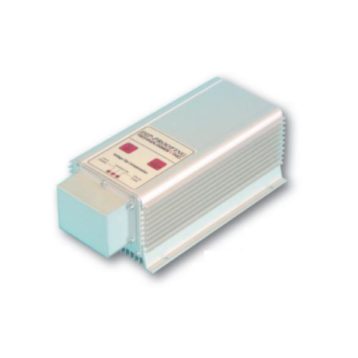

DPI 54S / 54L Manual (533.3 Kb) [PDF]

DPI54SUL-Manual (467.2 Kb) [PDF]

Bypass Switch (BPSW25A) Brochure (1.1 Mb) [PDF]

Options:

Two Level Timer Data Sheet (198.7 Kb) [PDF]

High Noise Immunity Data sheet (15.7 Kb) [PDF]

Inverter Running Monitor Output (19.6 Kb) [PDF]

Technical Literature:

DPI Case Study conducted by EPRI (400.7 Kb) [PDF]

Brief Intro to Power Quality Problems (16.8 Kb) [PDF]

Difference between VDC and DPI (1.1 Mb) [PDF]

Why a DPI should not be compared to a UPS (20.2 Kb) [PDF]

Applied Electronics in the field of Dip Proofing (86.5 Kb) [PDF]

Causes of Voltage Dips & Resulting Problems (143.9 Kb) [PDF]

Voltage Dip Effect on system w/ Motor Loads (97.7 Kb) [PDF]

Effects of Voltage Dips on Induction Motors (82.2 Kb) [PDF]

Behaviour of Contractors during Voltage Dips (90.5 Kb) [PDF]

Reducing the Effects of Customer Plant Dips (87.9 Kb) [PDF]

Planning Solutions to Voltage Dip Problems (22.6 Kb) [PDF]

User Manuals (Legacy Models):

DPI 53S / 54L Manual (889.7 Kb) [PDF]

DPI 52 Series Manual (809.1 Kb) [PDF]

Tools:

Interactive DPI Selector Guide

Sag Simulator User Manual (254.9 Kb) [PDF]

PSCOS – Programmable Static Switch (226 Kb) [PDF]